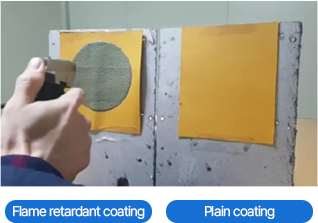

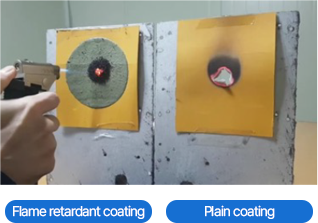

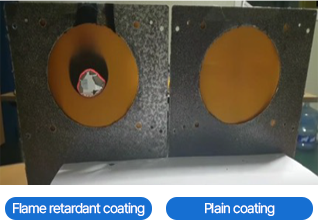

Fireproof membrane through fire extinguishing gas and immediate firing during flame contact

Fabric that can be formed to prevent flame ignition and transfer in case of fire

Fabric that can be formed to prevent flame ignition and transfer in case of fire

Fire and contact Fire Extinguishing gas eruptions and foam expanded flame retardants delay contact between the flame and the protected object for a long time, so they have excellent flame retardation performance.

Unlike conventional paints, it has excellent adhesion anywhere, and can be applied to any material in the fire-prone area.

Compared to traditional flame-resistant paint drying time (12 hours or more), shorter drying time is convenient and shorter working time.

Its own waterproof function prevents leakage and mold.

SPEC

| model | Anti Fire (Flame-Resistant Coating) / Anti Fire-F (Fire-Extinguishing and Flame-Resistant Coating) |

|---|---|

| Color | Gray, Black |

| Usage | Prevention of ignition and flame spread |

| Composition | Single-component |

| Volume Solids | 37% |

| Recommended Dry Film Thickness | 0.3mm ~ 0.5mm |

| Number of Coats | 1~2 coats |

| Theoretical Coverage | 0.74m²/L (at 0.5mm dry film thickness) / Surface condition and losses should be considered |

| Drying Time | 2 hours (Recoat interval: 2 hours) |

| Thinner | Water |

| Shelf Life | 6 months (Storage: 5°C ~ 28°C) |

Comparison of Traditional Flame-Resistant Paint and Our Product

| Application Range | Impact Resistance | Waterproof Function | Drying Time | |

|---|---|---|---|---|

| Our Product | Wide application range: wood, metal, plastic, wires, EPS, glass, etc. | No cracking | Yes (Similar to traditional waterproof urethane and epoxy) | 1~2 hours |

| Traditional Flame-Resistant Paint | For wood and metal | No flexibility, cracks upon impact | No | Separate base and topcoat (3~6 hours) |

TEST