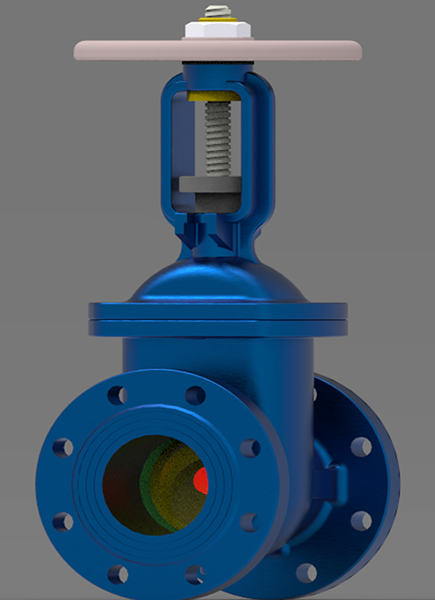

Tilting gate valves are optimized for blocking various fluids such as water, steam and oil, and are high-performance products that can be used reliably in power plants and plants.

This valve has revolutionized the main problems of conventional gate valves: long maintenance and high maintenance costs.

The tilting gate valve is detachable from the seat ring, which can significantly reduce maintenance costs, and the disk is designed with a tilting structure

The valve can be easily closed even with low torque, greatly increasing operational efficiency.

This valve has revolutionized the main problems of conventional gate valves: long maintenance and high maintenance costs.

The tilting gate valve is detachable from the seat ring, which can significantly reduce maintenance costs, and the disk is designed with a tilting structure

The valve can be easily closed even with low torque, greatly increasing operational efficiency.

Product Features

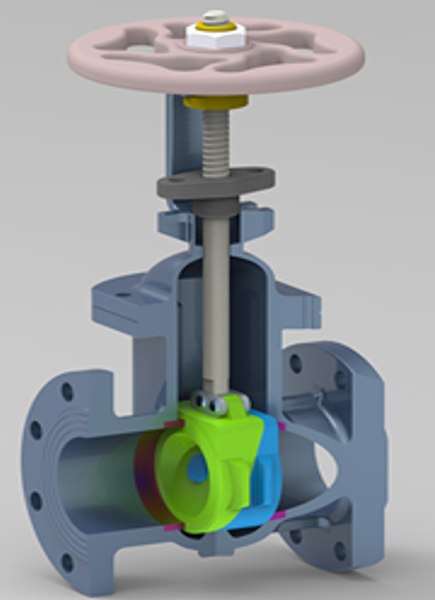

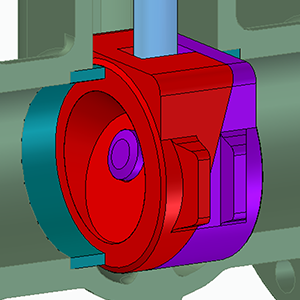

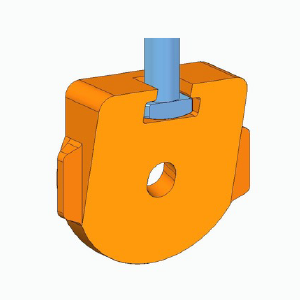

The disc is designed in two parts with inclined contact surfaces,

offering excellent sealing performance

Tilting structure disperses thrust direction,

enabling the valve to close easily with minimal torque

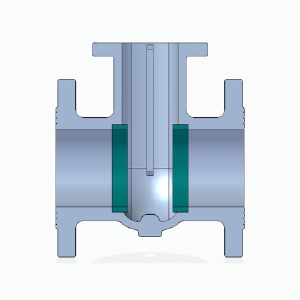

Designed with a parallel seat ring and detachable from the valve body,

Easy replacement of seat ring only during maintenance

The disadvantages of conventional gate valves are long maintenance time and

Effectively reduce high maintenance costs

Product Comparison

| Category | Traditional Gate Valve | Tilting Gate Valve |

|---|---|---|

| Disk Structure | One-piece, V-shape | Two-piece, Tilting type |

| Body Lapping | Very difficult (specialized tool required) | Easy (specialized tool required) |

| Maintenance Cost | High | Low |

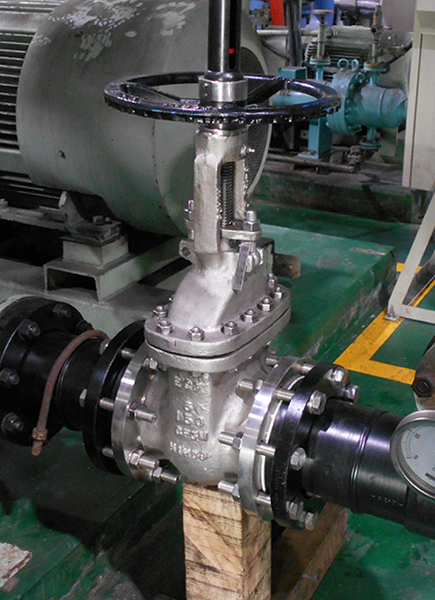

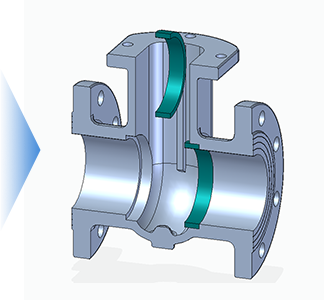

Installation Photos